The Rug Seller’s Guide On How A Rug Is Made

How a rug is made is often something that is mentioned in a description of a piece. But how many people really know what that means? The weaving process of rug production is a skilled art form which has been around for thousands of years. So understandably, the production types are complex and wildly different.

We’ve brought you a short guide to explain to you how a rug is made and the main processes used. There are five main types of weaving that rugs can be divided into; hand-knotted, hand-tufted, hand-hooked, flatweave and machine made.

To get your head around rug production, have a read of our break down of the things you need to know about how a rug is made.

Hand Knotted

A hand-knotted rug can sell for a few hundred pounds to a few hundred thousands of pounds. It is by far the slowest, most expensive way to produce a rug. This style of rug weaving has origins dating back over two thousand years. These rugs are painstakingly woven over months and even years.

Hand knotted rugs are made on a specially designed loom and are knotted by hand. How a rug is made depends on the size of the rug and the density of the knots. This can affect price depending on how much labour is involved – with the number of knots needed and the size of the loom.

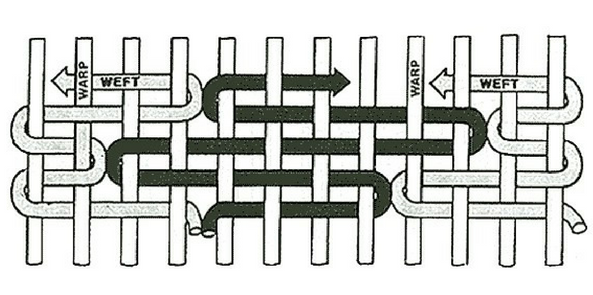

The vertical threads (warp) are tied to the loom, and the horizontal stings (weft) intertwines with the warp to create the foundation for the rug. The knots are then tied to the warp threads, by the weaver cutting the thread and tying it by hand. This makes up the “pile” of the rug.

This is a very tedious and time-consuming operation. A standard rug can have up to 1000 knots per square inch, and a skilful weaver would be able to do 6 knots per minute.

Techniques

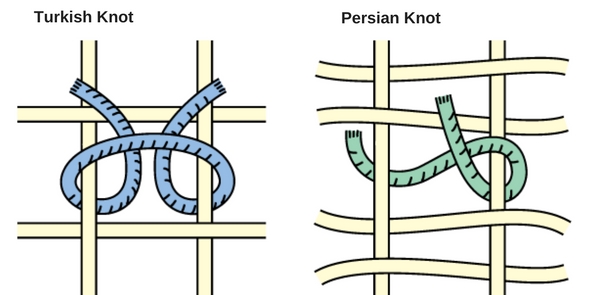

There are two main types of hand-knotting techniques used; the Persian knot and the Turkish knot. The Persian knot is asymmetrical and leaves a gap, whereas the Turkish knot is symmetrical. The method used is usually dependent on where the origin of the rug is. Potentially even the patterns as Persian knots are better at intricate patterns.

Through this time consuming operation, these types of rugs are carefully created as a hugely resilient product. They can be repaired and cleaned without wearing out. Hand knotted rugs can last up to 20 years due to the care and craftsmanship that goes into weaving them by hand. They can withstand high traffic areas.

Hand-knotted rugs really are an investment of time from the weaver which results in a fabulously high-quality end product which is truly one of a kind.

Hand Tufted

Hand tufting is the fastest method of making a rug by hand, it is used for both contemporary, modern and traditional designs. Wool is often the norm for hand tufted types of rugs, as well as many other fibres used including acrylic, viscose, jute and polyester.

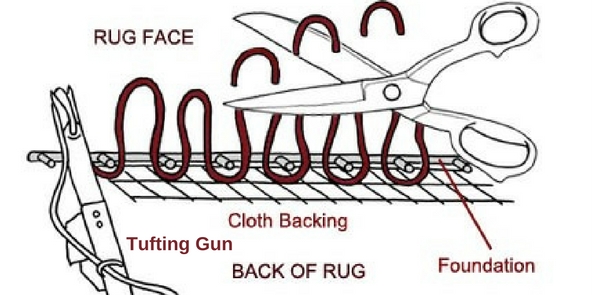

Tufted rugs are created without knots, and instead use a loop of yarn being pulled through the rug’s backing. This looping is often done with a ‘tufting gun’, which is why this method of rug production is much cheaper due to it being less labour intensive.

The canvas backing itself is printed with the overall design, called a ‘cartoon’ which the weaver follows as a guide. This helps to guide the ‘tufting gun’ to produce an even pattern when pushing the loops through.

Once the loops of yarn are pulled through the backing, the further layers of foundation backing are applied. Firstly, a plastic or rubber grid called the scrim is added, which is then secured with latex glue. Then finally on top of that, a protective backing is added.

Once this has been done, the weaver will shear the rug to cut the loops which then consequently creates the pile.

Hand-tufted rugs are less labour intensive with how a rug is made, but look very similar to hand-knotted rugs. They tend to be cheaper and aren’t quite as well wearing, but still last between 12-15 years.

Hand Hooked

Hand hooked rugs use a form of weaving that is similar to tufting, except the loops remain intact. It uses a gun type of instrument to aid the weaving process, which makes it less time to consume than hand knotting. Then, instead of the yarn being sheared, the loops remain intact and create a characteristic embroidered look to it.

There is also petite point hooking, which is using a very fine needle. But this is much more time consuming and therefore makes the rugs much more expensive. Hand hooked rugs are able to give intricate designs with bright colours due to the precision from this type of weave.

Hand hooked rugs aren’t very hard wearing, and tend to wear out from between 5 and 15 years depending where they are placed. They are better suited for rooms with less footfall like bedrooms. This is because they aren’t very durable and will last longer in these sort of spaces. For more information on what type of rugs are best for what room in our posts on living room rugs or hallway runners.

Flat-Woven

Flatweave rugs are called that as they have no pile, and lie flat. Due to how a rug is made, they have a particular weaving style so that the yarn is completely intertwined. Rather than protruding to create a pile. They can be made from synthetic or natural fibres and wool, and most natural fibre rugs tend to be flat woven.

Dhurries and Kilims are always flatweave rugs and tend to characterised by their place of production. Dhurries are characteristically from, India and Kilims are based around Turkey and Egypt historically.

Flatweave rugs can be hand weaved or machine made, and due to the nature of the weave being so thin and close. They are often reversible as you can see the weave from both sides.

It’s made by using the warp strands to weave with the weft strands as the foundation of the rug as well as to make the pattern. The texture and design of the rug is dependent on the changing colour, size and texture of the weft strands.

Flatweave rugs are not as thick as hand-tufted or knotted rugs and aren’t as durable. Also, due to their lack of pile, stains show up easily. However, they are much more reasonably priced than hand-woven rugs. They are also able to produce vivid colours in the intensity of the weave.

Machine Made or Power Loomed

By far the most popular weaving method for rugs in Europe and America. Machine woven rugs are created on high powered looms. These rugs are generally manufactured with materials including wool and synthetic fibres such as polypropylene, nylon, polyester, acrylic and art silk.

This process has the least amount of labour, as it is almost exclusively done with machines rather than anything by hand – unlike the other processes we’ve mentioned.

How a rug is made on a machine is by interlacing the face yarns and backing yarns (the foundations for the face fibre) in order to craft a completed woven product. These types of rugs and production eliminates the need for a secondary backing.

Machine made rugs usually have a lifespan of about 20 years or less, depending on the quality and fibre used. The benefit of machine made rugs is that they have many of the qualities of handmade rugs but cost significantly less.

Flokati

Flokati is another type of rug make, but it is very specific to a particular type of rug and production. It has to be produced in a certain way to claim the name ‘Flokati’ rug, as is enforced by the Greek government.

The rugs are made completely from wool, even down to the backing part of the rug where the yarn is pulled through. The wool is spun by spindles into yarn to begin the weaving process.

For Flokati rugs, they have specifications of how a rug is made to earn the name. Before weaving begins, the yarn needs to be washed under pressurised water to get its distinctive soft fluff and pile rather than a normal woollen feel. Traditionally it is washed for 40 hours under a waterfall of the Pindus mountains to cleanse and shrink the yarn to soften it this way.

The yarn is then made to create long loops and sheared, similarly to the hand-tufted method. The ‘Flokati’ rug has gained popularity in recent years. Since 1966 the Greek government laid out specifications for the rug to meet to be named an authentic Flokati. It must be washed under pressured water, and contain a minimum amount of 1800 grams of pure wool.

Thoughts?

The process of weaving can be a complicated idea to grasp, with all the intricacies of each process that have developed over thousands of years.

Rugs can vary from country to country through weaving practices differing geographically. Even from what material they are made from can make a significantly different end product.

If you want a better idea about materials and what they mean. Have a read of our blog posts on how to choose a rug for your living room or hallway.

Hopefully, you’ve found our guide helpful to start to understand the more technical side of rugs and how they’re made. If there’s anything you want to know more about, let us know in the comments!

Updated November 2021

Leave A Comment